Filtration is a process that is applied more often than we realize. It is used all around us. It can be as simple as using a sieve after boiling rice to separate the rice from water or as complex and large-scale as purifying drinking water for an entire apartment complex.

Just about any business, institution or industry uses filtration as a part of their operation. Separating metals such as gold from minerals is an example of an industrial application. Sewage treatment is yet another.

Filtration entails the utilization of gases too. It is essential for purifying the air in industrial plants to meet regulatory safety standards. Because of its diverse range of applications, filtration is a crucial step in many industrial processes. As you can imagine, without proper filtration systems in place, things can go awry quickly.

That’s why at SE Coopermatics, we make it our mission to supply high-quality, reliable filtration systems because we understand the importance of having the right filtration equipment to assist in operations in your industry.

Listed below are some of the common functions and advantages of filtration systems in different industries.

Protect Equipment

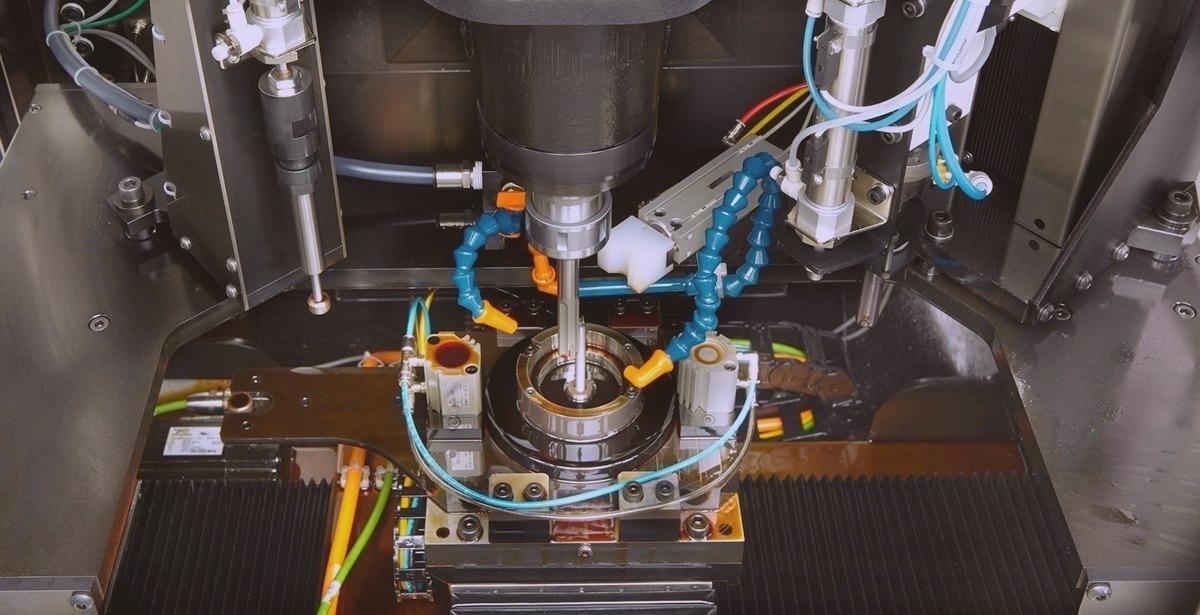

Filtration is an essential process in industrial manufacturing. It helps in protecting the coating of expensive machinery that is used regularly. When particles are not filtered out properly, they can damage the equipment, which can ultimately lead to system failures. This will result in huge costs incurred in repairs or replacing parts of the equipment.

For example, leftover particles in pipes can erode the metal, reducing the efficiency of the machine, leading to malfunctions in the entire production process.

Purification

As you already are aware, one of the most common functions of the filtration process is purifying water. It plays a crucial role in eliminating sediment, sand, gravel, carbon and other suspended particles to bring safe drinking water to our homes.

Similarly, filtration plays the role of purifying components in industries too. Filtration systems are extremely important to keep components like water, coolants, oils and chemicals clean and free of contaminants. Without filtration, there would be a large wastage of non-renewable resources which would in turn greatly affect the environment.

Recycling for environment sustainability

From experience, we know an effective filtration system can enhance coolant or machine fluid’s life by 10 fold. This constitutes a large chunk of the waste disposed for most manufacturing companies using metals as base materials. By recycling these fluids, the amount of waste discharged into the environment can be drastically reduced, which should be an obligation all manufacturing industries should voluntarily fulfill.

Moreover, recycling practices and environmental sustainability are becoming a huge factor in enhancing sentiments customers and investors have towards your company. Hence, publicity gained from such ethical practices can boost your brand value.

Systematic Waste Disposal

Filtration systems are designed with the intention to separate particles from each other. Like straining rice, many industrial and manufacturing processes need to isolate their solids, gases, oils, water and other fluids for systematic and efficient removal of waste. Being able to separate waste materials, each waste type can be treated appropriately before disposal.

Filtration systems serve as a cost-effective alternative to chemical treatment plants and contract hauling of waste.

Safety

Installing filtration systems can help keep workplaces safe for employees. Most devices like filtration systems, chip handlers and oil recovery systems are now automated which means these systems are equipped to filter out even the tiniest metal particles from other metallic or non-metallic components, with little to no manpower required. This helps keep employees coming in contact with highly contaminated and hazardous materials. It even helps companies comply with safety and quality standards.

Efficiency

Filtration helps many industrial operations flow smoothly, more efficiently and saves time. Take the case of oil rigs. When bringing oil up out of the ground, sand and debris get mixed in with the oil. Placing filters along the source can help get rid of some of those particles on the way up, saving time and effort.

Filtration systems can be a boon to many industries and their applications. The tricky bit is in finding the right filtration system that fits perfectly with your production process. That’s where SE Coopermatics steps in. We provide the necessary guidance in finding the filtration systems you are looking for. Get in touch with our team for enquiries.