FILTRATION SYSTEMS

Pressure Pre-Coat

The recommended option for fine filtration, reducing particles down to 5 microns or less.

Paper Band Filter

The simplest filtration device that uses special grade filter papers for efficient filtration.

Vacuum Filter

An efficient filtration system that uses the vacuum principle to filter high volumes of fluid.

Pressure Bed Filter

Applying pressure pneumatically or hydraulically on a flat bed for high volume fine filtration.

Magnetic Separator

A portable pre-filter solution to separate metallic (ferrous/non-ferrous) particles from fluids.

Sump Cleaner

An essential device to keep coolant tanks clean to cut costs and protect your equipment, fluid and employees.

Cartridge/Bag Filter

Pressure Filters using cartridges or bags for filtering extremely fine particles down to 0.2 microns.

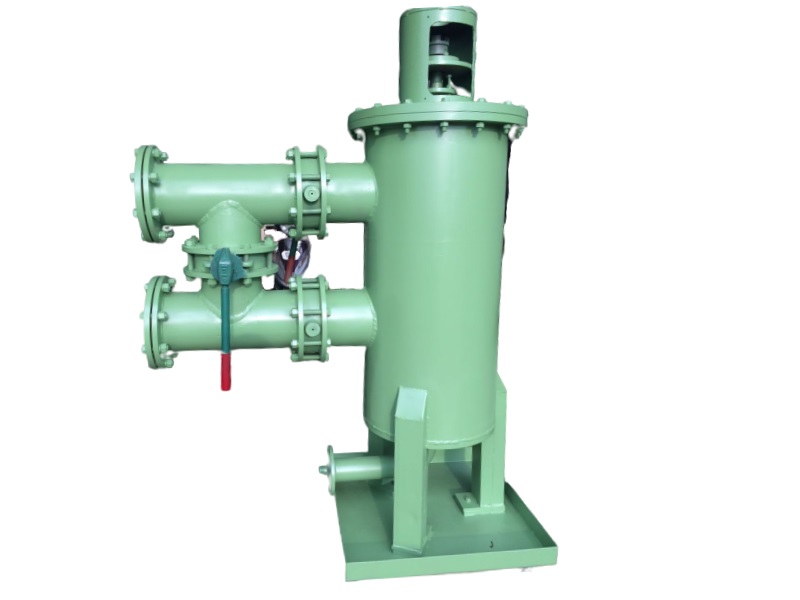

Self Cleaning Filter

A unit that continuously filters fluids with large particles and at the same time cleans the insides of the filter.

Oil Skimmer

An economical device to remove tramp oil floating on top of coolant and keep coolant active.

Centralized filter

A convenient option for large facilities to streamline coolant and pressure distribution to multiple machines.

OIL RECOVERY SYSTEMS

Sludge Drying Unit

A post-filtration portable unit that can extract oil from sludge to minimize loss of oil and costs.

Oil Recovery Press

Turn waste into profits - recover up to 40% residual oil and increase the value of the swarf.

Chip Wringer

Extract upto 90% of oil that are stuck on metal chips generated during machining process.

Chip Handling Systems

Scraper chip conveyor

Uses scraper plates on a chain to transport swarf. Effective for transferring small chips in bulk.

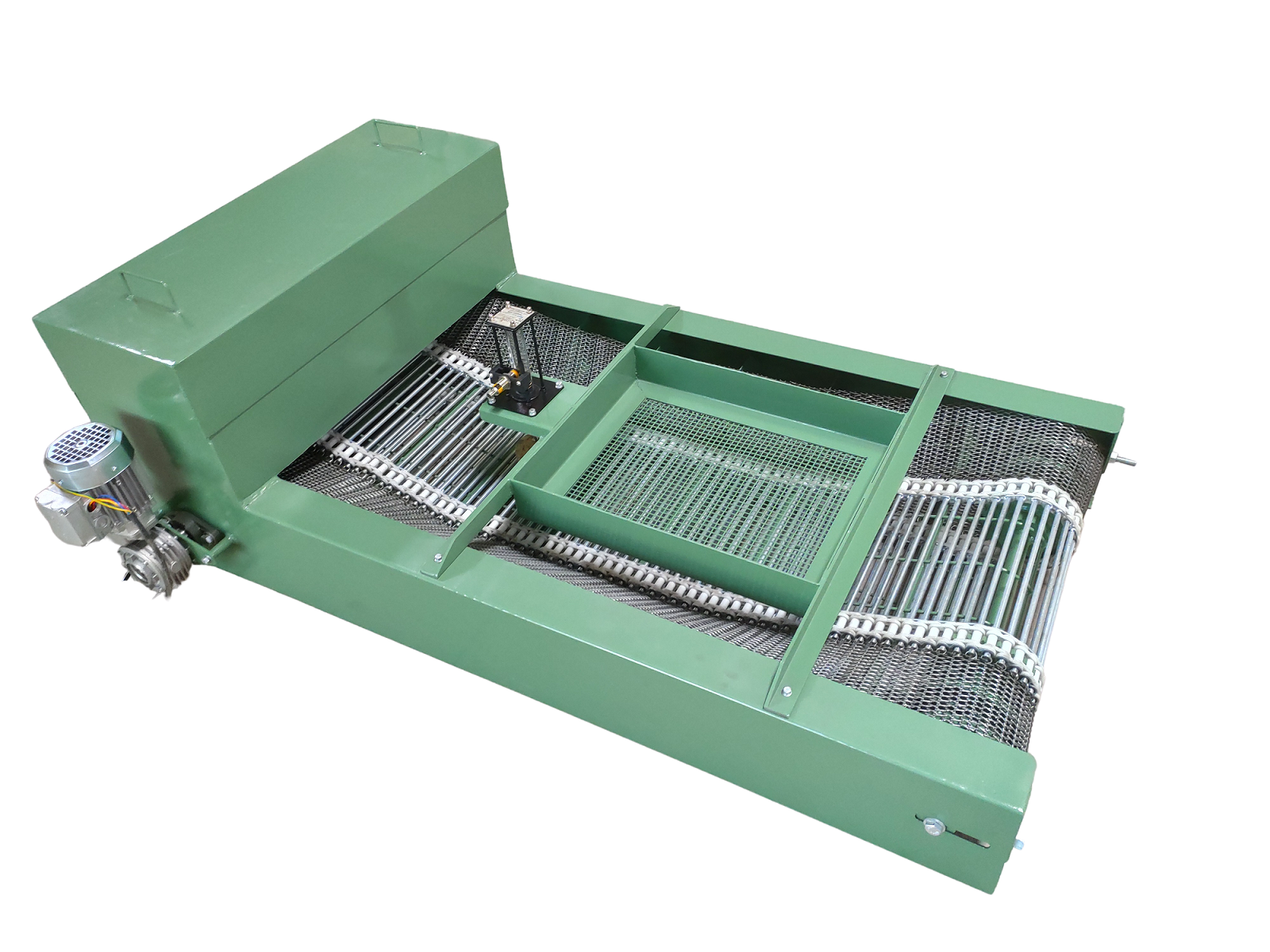

Slat Chip Conveyor

Uses slats or cleats on a chain to transport swarf. Effective for transferring long and curly chips.

Screw chip conveyor

Used for the removal of chips or powder. Used for controlled movement of chips.

Magnetic chip conveyor

Operated with permanent magnets. Effective for small chips or burrs of ferrous metals.

Centralized chip conveyor

Streamlining chip collection by transferring all types of chips from a group of machines to a centralized location.