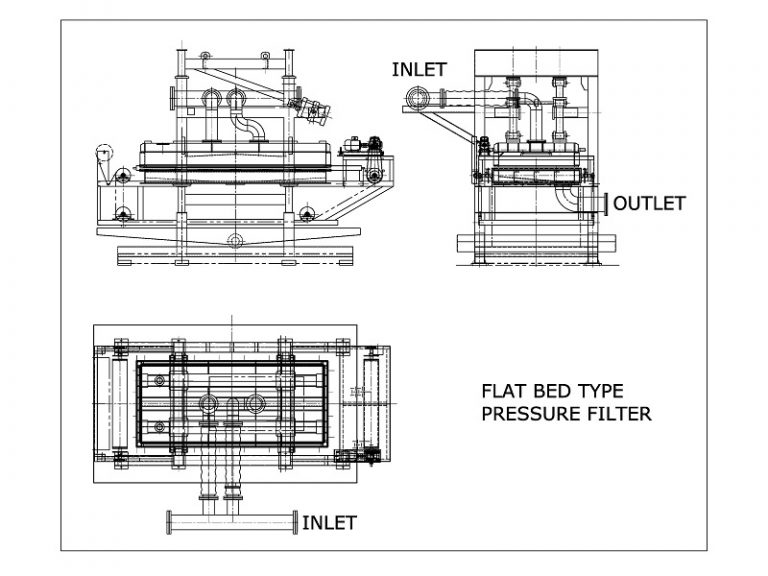

FLATBED PRESSURE FILTRATION SYSTEM

The flatbed pressure filtration system is a type of pressure filter where a suspended solid such as precipitate is separated from the liquid by straining it – under pressure – through a porous medium that can be penetrated easily by liquid.

The device is used for filtering grinding/ honing/ super finishing coolant from a group of machines where the contaminants are in powdery/ particulate form.

The flatbed pressure filtration system is a highly evolved form of the paper band filtration system. It utilizes a lower footprint to achieve the same LPM of filtered coolant output. It also considerably lowers filtration medium consumption.

The contaminated coolant from a group of machines is typically collected from each machine in underground coolant trenches, and flows by gravity to the flatbed pressure centralized filtration system. The contaminated coolant is fed through a filter medium under positive pressure provided by a transfer pump through the top shell by opening the actuated valve. The contaminated coolant is discharged onto a diffuser, to endure its flow onto the filter medium. The contaminants in the coolant are blocked by the filter medium to form a contaminant cake. The clean coolant flows past the medium into the clean coolant chamber located below the filter medium.

ADVANTAGES

- Achieve lower footprint per litre of filtered dirty oil.

- Reduce the filtration medium consumption per unit weight of dirt removed.

- Back washable nylon and SS mesh can be used to reduce consumables.

- Fully automated PLC.

- Filter media can be changed.

- Can use with pre-coat media to achieve very fine filtration level.

APPLICATIONS

- Steel grinding

- Cast iron grinding

- Honing