PAPER BAND FILTER

Paper band filters are one of the simplest forms of separating particles from all types of fluids. Its cost-effective nature and design make this filter a popular choice for many industrial applications. The filtration level ranges from 15 to 100 microns, depending on the type of application and media used.

The dirty coolant liquid from machining centers is passed through a special filter paper where all dirt particles (ferrous and non-ferrous), grinding grit, etc. are collected. When the porosity of the filter paper fills up, the dirt level in the paper rises till it touches the float switch. The float switch will then kickstart a geared motor to remove the used filter paper and produce a fresh one in its place without disrupting the filtration process.

The filter papers are available in the form of rolls. The common filter paper materials used are polypropylene and polyester, which are selected based on the type of liquid being filtered. The nylon mesh type is our latest addition, where the filter paper can be reused. This is mainly used in grinding operations.

TYPES

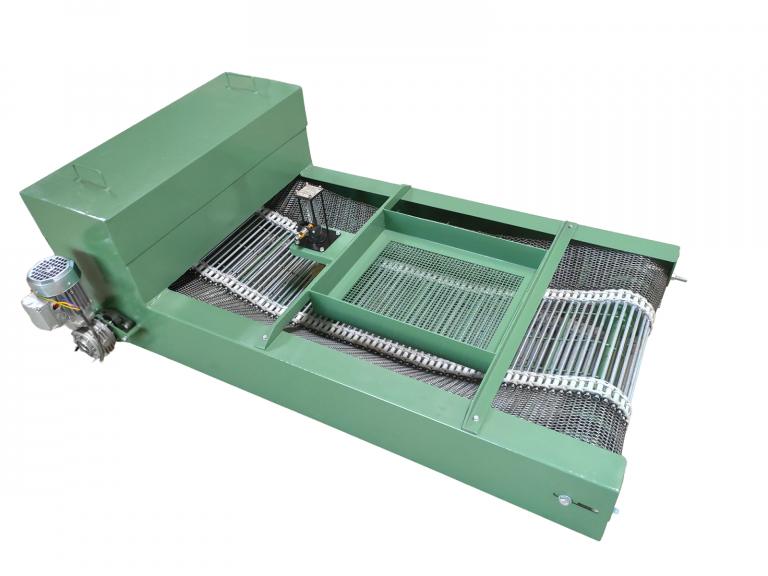

In a conveyor type paper band filter, the filter band is laid on a conveyor and filter medium is added based on the filtration application. The filter unit is installed above the clean liquid tank. The dirty liquid falls on the band while the filtered liquid drops into the clean tank. The clean liquid is then pumped back into the machine. The level of dirt accumulated on the band is monitored by a sensor. Once the accumulation has reached its limit, the dirty band is moved out and the dirt is disposed.

The compact paper band filter is designed for space efficiency. These devices work on the same principle but are relatively smaller compared to conveyor-type paper band filters. Magnetic separators and/or oil skimmers can be integrated with compact type band filters for optimum filtration efficiency.

ADVANTAGES

- Suitable for filtering fine particles.

- Filtration capacity: 50 to 1,000 LPM / 13 to 264 GPM.

- Very low maintenance required.

- The unit is mounted on rollers above the clean tank for tank cleaning convenience.

- Fully automated operation.

- Compact design to suit the site space requirements.

- Ideal for individual machines.

- Filtration quality can be improved by integrating it with a magnetic separator.

- Separate drive available to accommodate magnetic separator.

APPLICATIONS

- Grinding

- Honing

- Lapping

- CNC tool and cutter grinding

- Tube and rolling mills

- Wire drawing

- Plastic recycling

- Water treatment